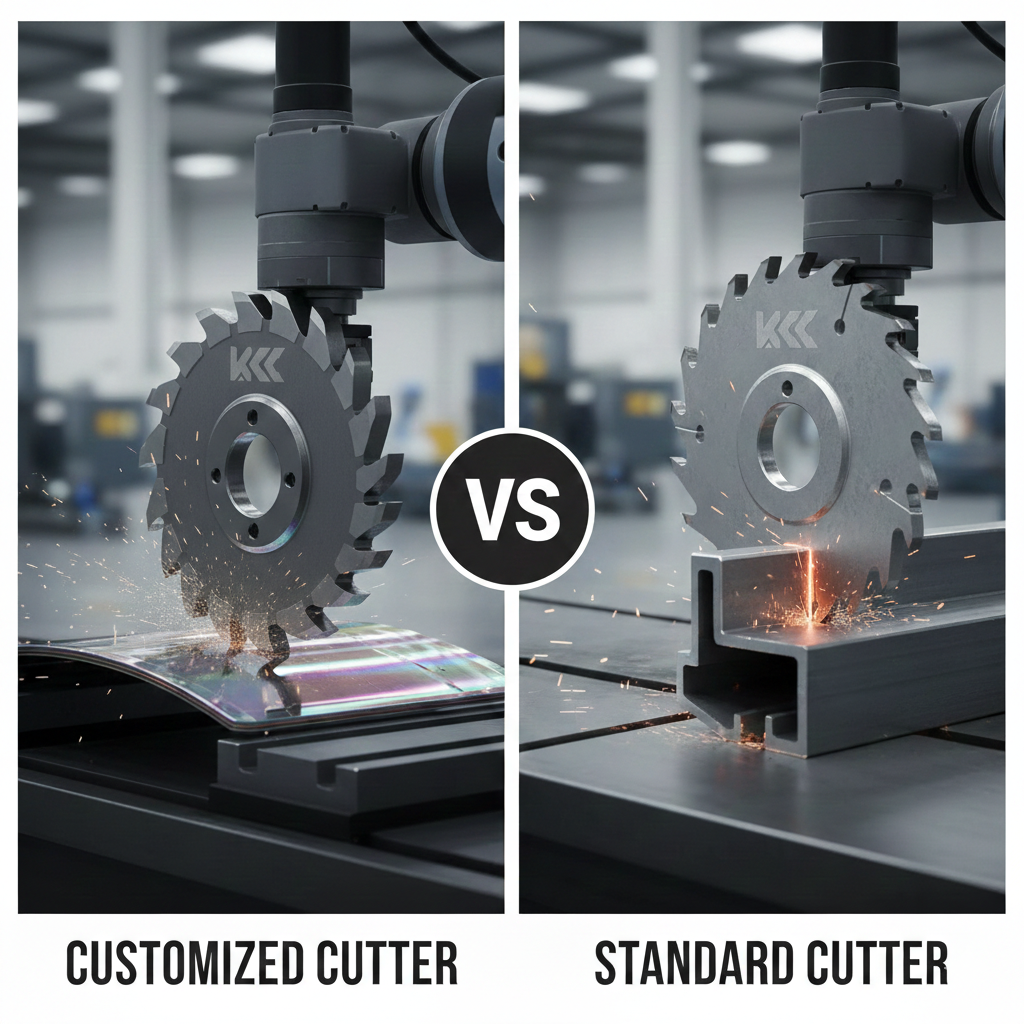

Selecting the right cutting tool is a critical decision in any machining operation. One of the most common questions faced by manufacturers and machinists is whether to use standard tools or invest in customised solutions. Understanding the difference between standard vs customised cutters helps businesses make informed choices that balance performance, cost, and production efficiency.

Both options have their advantages, and the right choice depends on the specific machining application, production volume, and accuracy requirements.

What Are Standard Cutting Tools?

Standard cutting tools are off-the-shelf products manufactured in common sizes and geometries. These tools are readily available and designed to meet the needs of a wide range of general machining applications.

Standard cutting tools include end mills, drills, slotting cutters, and slitting cutters used in everyday manufacturing operations.

Advantages of Standard Cutting Tools

1. Immediate Availability

Standard tools are widely stocked and easily accessible, making them ideal for urgent production needs or maintenance work.

2. Lower Initial Cost

Compared to custom tools, standard cutters typically have a lower purchase price, making them suitable for small-scale or short-term machining jobs.

3. Proven Performance

Standard tools are tested across a wide range of applications, offering predictable and reliable performance in common machining conditions.

These benefits make standard tools a practical choice in many machining applications.

Limitations of Standard Cutting Tools

While standard tools are versatile, they may not always deliver optimal results for specialised or complex machining requirements.

Common limitations include:

- Compromises in tool geometry

- Limited size and profile options

- Reduced efficiency in complex operations

These limitations often lead manufacturers to consider customised solutions when standard tools fall short.

What Are Customised Cutting Tools?

Customised cutting tools are designed and manufactured to meet specific application requirements. Tool dimensions, geometry, and cutting characteristics are tailored based on the workpiece material, machine type, and production goals.

High-performance customised cutting tools are commonly made from solid carbide to ensure rigidity and long tool life.

Advantages of Customised Cutters

1. Optimised Performance for Specific Applications

Customised tools are engineered to match exact machining needs. This precision allows better cutting efficiency and improved results compared to standard tools.

The performance advantage is a key factor when evaluating standard vs customised cutters.

2. Improved Accuracy and Surface Finish

By eliminating compromises in tool design, customised cutters deliver tighter tolerances and superior surface finishes.

This is especially important in high-precision industries such as automotive, aerospace, and tooling.

3. Longer Tool Life

Customised carbide cutters distribute cutting forces more evenly, reducing wear and extending tool life.

This results in fewer tool changes and more consistent production output.

4. Reduced Number of Machining Operations

Custom tools can combine multiple cutting functions into a single tool, reducing setup time and improving productivity.

This efficiency is a significant advantage in complex machining applications.

When Should You Choose Standard Cutters?

Standard cutters are best suited for:

- General-purpose machining

- Low to medium production volumes

- Simple part geometries

- Maintenance and repair operations

In these scenarios, standard cutting tools provide a cost-effective and reliable solution.

When Should You Choose Customised Cutters?

Customised cutters are ideal when:

- Tight tolerances are required

- Complex profiles or non-standard dimensions are involved

- High-volume production demands consistency

- Tool life and productivity are critical

In such cases, investing in customised tools offers clear advantages in the standard vs customised cutters comparison.

Cost Considerations and Long-Term Value

While customised tools involve higher initial investment, they often deliver greater long-term value through:

- Reduced tool consumption

- Lower scrap rates

- Improved machine utilisation

- Higher productivity

Evaluating cost based on total production efficiency rather than tool price alone helps determine the right choice.

Role of Material Selection

Material hardness and machinability significantly influence tool choice. Hard or abrasive materials often benefit from customised carbide cutters, while softer materials may be efficiently machined using standard tools.

Matching tool selection to material requirements ensures optimal performance and tool longevity.

Importance of Supplier Expertise

Choosing the right tool supplier is essential, especially when investing in customised solutions. Experienced manufacturers provide technical support and application-specific recommendations.

This expertise helps manufacturers make informed decisions when evaluating standard vs customised cutters.

Conclusion

Understanding the differences between standard vs customised cutters allows manufacturers to choose the most effective tooling strategy for their operations. While standard tools offer convenience and affordability for general applications, customised tools deliver superior performance, accuracy, and efficiency for specialised machining needs.

By assessing production requirements, material characteristics, and long-term cost implications, businesses can select the right cutting tools that support quality, productivity, and sustainable growth.