Jewellery manufacturing is a unique blend of craftsmanship and precision engineering. Unlike heavy industrial machining, jewellery production involves working with small, delicate components made from precious metals and alloys where accuracy, surface finish, and consistency are critical. Even minor errors can lead to material loss, increased cost, or compromised product quality.

To meet these exacting standards, manufacturers rely on precision cutting tools for jewellery manufacturing that are specifically designed to deliver controlled cutting, fine detailing, and exceptional surface quality. The right cutting tools play a decisive role in maintaining both aesthetic appeal and dimensional accuracy in jewellery components.

Understanding the Machining Challenges in Jewellery Manufacturing

Jewellery machining presents distinct challenges compared to conventional manufacturing:

- Extremely small component sizes

- Tight dimensional tolerances

- High-value materials such as gold, silver, platinum, and alloys

- Requirement for superior surface finish

- Minimal material wastage

These factors make standard industrial tools unsuitable for many jewellery applications. Specialised jewellery machining tools are required to achieve precision without damaging or deforming delicate parts.

Common Materials Used in Jewellery Manufacturing

Jewellery manufacturers work with a wide variety of materials, including:

- Gold and gold alloys

- Silver

- Platinum and palladium

- Brass and copper alloys

- Stainless steel for fashion jewellery

Each material has unique machining characteristics. Selecting the correct jewellery cutting tools ensures smooth cutting, reduced burr formation, and consistent results across different metals.

Importance of Precision Cutting Tools in Jewellery Production

The use of precision cutting tools for jewellery manufacturing ensures that every component meets exact design specifications. These tools are engineered to deliver:

- Clean and accurate cuts

- Fine detailing on intricate designs

- Smooth surface finish requiring minimal polishing

- Repeatability across batch production

Precision tooling is essential not only for quality but also for maintaining efficiency and reducing material waste.

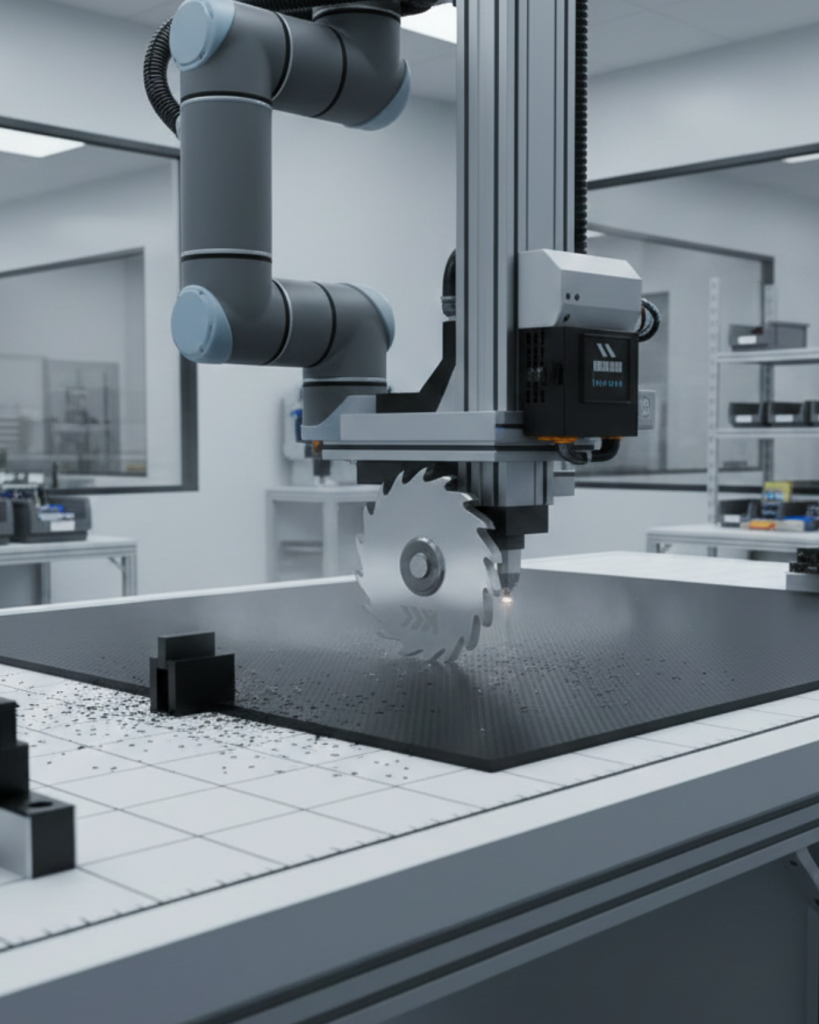

Types of Cutting Tools Used in Jewellery Manufacturing

Micro End Mills

Micro end mills are widely used for fine profiling, engraving, and detailed shaping. Their small diameter allows precise control when machining intricate jewellery components.

Slitting and Slotting Cutters

Slitting cutters are used for parting operations and creating narrow grooves. High-quality cutters minimise burrs and ensure accurate separation of small components.

Engraving Tools

Engraving cutters are used for decorative patterns, logos, and fine detailing. Sharp edges and controlled geometry are essential for clean engraving results.

Role of Solid Carbide in Jewellery Cutting Tools

Solid carbide is the preferred material for most jewellery cutting applications due to its superior hardness and edge retention. Carbide cutters for jewellery offer:

- Exceptional wear resistance

- Ability to maintain sharp cutting edges

- Stability during high-speed machining

- Longer tool life compared to HSS tools

These benefits make carbide tools ideal for precision-focused jewellery machining.

Benefits of Using Carbide Cutters for Jewellery

Using carbide cutters for jewellery provides several advantages:

- Improved surface finish quality

- Reduced tool deflection during cutting

- Consistent dimensional accuracy

- Lower frequency of tool replacement

These advantages directly support high-quality output and cost control in jewellery manufacturing operations.

Precision Machining for Jewellery Applications

Modern jewellery manufacturing increasingly relies on CNC and micro-machining centres. These machines require tools that can perform accurately at high speeds while maintaining stability.

Precision machining for jewellery demands tools with:

- Optimised cutting geometry

- Fine edge sharpness

- Balanced tool design

- Compatibility with small-diameter tool holders

Precision cutting tools designed specifically for jewellery applications meet these requirements effectively.

Importance of Tool Geometry and Finish

Tool geometry plays a critical role in jewellery machining. Proper rake angles, clearance, and edge sharpness ensure smooth cutting and prevent material tearing.

Polished cutting edges and low-friction tool surfaces further enhance chip evacuation and surface quality, especially when working with soft precious metals.

Reducing Material Waste and Production Cost

Precious metals are expensive, making material wastage a major concern. Accurate jewellery cutting tools help minimise scrap and rework by delivering consistent results from the first cut.

Efficient tooling reduces errors, shortens production cycles, and improves overall profitability for jewellery manufacturers.

Customised Cutting Tools for Jewellery Manufacturers

Standard tools may not always meet the unique requirements of jewellery designs. Customised tools allow manufacturers to match exact profiles, dimensions, and cutting characteristics.

Custom precision cutting tools for jewellery manufacturing help achieve complex shapes and intricate details while maintaining consistency across production batches.

Selecting the Right Tool Manufacturer

Choosing a reliable tool manufacturer is critical for jewellery applications. Experienced manufacturers understand the precision requirements and material challenges involved in jewellery machining.

Working with specialists ensures access to high-quality jewellery machining tools designed to deliver accuracy, durability, and repeatable performance.

Conclusion

Jewellery manufacturing demands the highest level of precision, control, and surface quality. Using the right precision cutting tools for jewellery manufacturing ensures accurate machining, minimal material loss, and superior finish quality.

From micro end mills to advanced carbide cutters for jewellery, specialised tools enable manufacturers to meet both aesthetic and technical requirements. By investing in high-quality jewellery cutting tools and precision machining solutions, jewellery manufacturers can achieve consistent results, improved efficiency, and long-term production reliability.