General engineering and fabrication units form the backbone of industrial manufacturing. From producing machine components and structural parts to fabricating assemblies for automotive, infrastructure, and industrial machinery, these units depend heavily on reliable and precise cutting tools. Selecting the right tools is not just about cutting metal, it directly affects productivity, dimensional accuracy, surface finish, tool life, and overall operational cost.

Understanding the cutting tool requirements for general engineering is essential for manufacturers aiming to maintain consistent quality while meeting tight production schedules. With increasing demand for precision and efficiency, modern fabrication units must rely on cutting tools that can handle varied materials, machining conditions, and production volumes without compromising performance.

Understanding the Nature of General Engineering & Fabrication Work

General engineering and fabrication units typically deal with a wide range of operations, including:

- Milling, turning, drilling, and slotting

- Structural fabrication and part assembly

- Low to medium batch production

- Machining of diverse materials

Unlike specialised industries that focus on a single product type, general engineering workshops handle multiple jobs daily. This diversity makes selecting the right general engineering cutting tools critical for smooth operations.

Fabrication environments demand tools that are versatile, durable, and capable of performing under varying cutting loads. As a result, cutting tools must strike a balance between performance, adaptability, and cost-effectiveness.

Key Materials Machined in Fabrication Units

One of the most important factors influencing the cutting tool requirements for general engineering is the range of materials commonly processed. These include:

- Mild steel and carbon steel

- Stainless steel

- Cast iron

- Aluminium and non-ferrous alloys

- Engineering plastics

Each material behaves differently under machining conditions. For example, stainless steel requires tools with higher wear resistance, while aluminium benefits from sharp cutting edges and excellent chip evacuation. This variation makes tool selection a strategic decision rather than a standard purchase.

Essential Cutting Tools Used in Fabrication Units

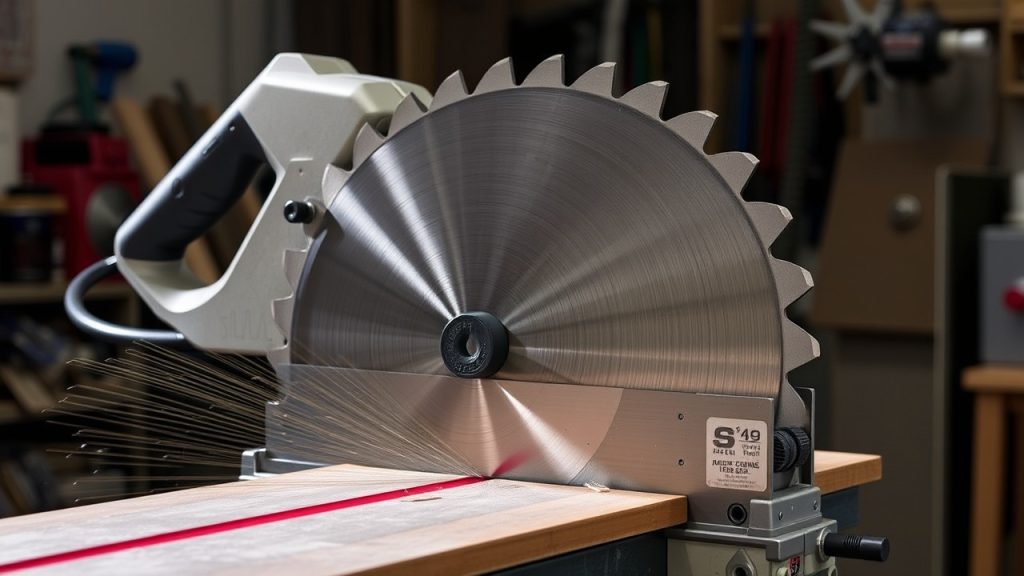

Milling Cutters

Milling is one of the most common operations in fabrication units. End mills, face mills, and slotting cutters are widely used to shape components and create precise features. High-quality milling cutters ensure accuracy, reduce vibration, and deliver consistent surface finishes.

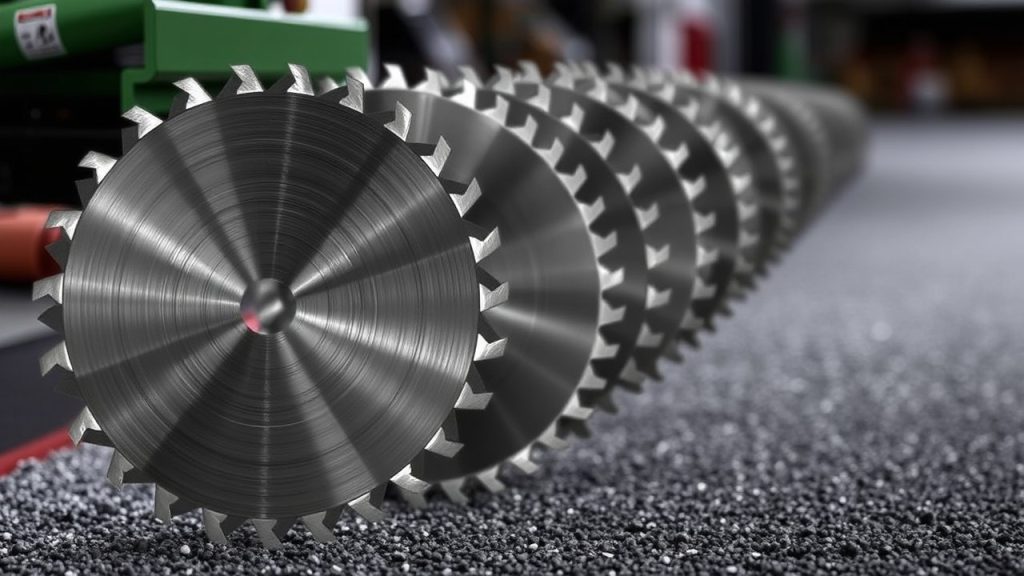

Slitting & Slotting Cutters

Slitting and slotting operations are critical in fabrication work, especially for cutting sheets, creating grooves, or separating components. Reliable fabrication cutting tools ensure clean cuts with minimal burr formation, reducing secondary finishing work.

Drilling Tools

Drills are essential industrial machining tools used daily in fabrication shops. The right drill geometry improves hole accuracy, chip evacuation, and tool life, especially when machining steel and alloy materials.

Importance of Tool Material Selection

Tool material plays a vital role in determining performance and durability. The most commonly used tool materials in fabrication units include:

High-Speed Steel (HSS)

HSS tools are widely used due to their toughness, affordability, and ease of re-sharpening. They are suitable for moderate cutting speeds and are ideal for smaller workshops or flexible production environments.

Solid Carbide Tools

Carbide tools are preferred when higher cutting speeds, better surface finish, and longer tool life are required. Carbide cutters for fabrication offer excellent hardness and wear resistance, making them suitable for stainless steel, cast iron, and high-volume machining operations.

Selecting between HSS and carbide depends on workload, material hardness, machine capability, and production goals—an important consideration within the overall cutting tool requirements for general engineering.

Tool Geometry and Its Impact on Performance

Tool geometry directly influences cutting efficiency and tool life. Factors such as rake angle, clearance angle, and edge sharpness must be optimised for the material being machined.

In fabrication units, improper tool geometry often leads to:

- Excessive tool wear

- Poor surface finish

- Increased cutting forces

- Tool breakage

Well-designed general engineering cutting tools with optimised geometry ensure smooth cutting action, stable machining, and consistent output quality.

Durability and Tool Life Expectations

Fabrication units operate under demanding conditions where downtime can be costly. Therefore, durability is a critical factor when defining cutting tool requirements for general engineering.

High-quality tools:

- Maintain dimensional accuracy over extended use

- Resist wear and chipping

- Reduce frequent tool changes

- Improve overall machine utilisation

Longer tool life directly translates to reduced tooling costs and improved productivity—key objectives for any fabrication business.

Compatibility with CNC and Conventional Machines

Modern fabrication units often operate a mix of CNC machining centres and conventional milling machines. Cutting tools must be compatible with both setups.

Precision-balanced tools are essential for CNC machines, while robust and forgiving tools are better suited for manual or semi-automatic machines. Versatile industrial machining tools that perform consistently across different machines provide operational flexibility and cost savings.

Role of Customised Cutting Tools in Fabrication

Standard tools may not always meet specific fabrication needs, especially for unique component designs or non-standard dimensions. Customised tools play an important role in meeting specialised machining challenges.

Custom carbide cutters for fabrication can be designed to:

- Match exact slot widths and depths

- Improve machining efficiency

- Reduce multiple operations into one

- Enhance consistency in repeat jobs

For fabrication units handling diverse projects, customised solutions offer a competitive advantage.

Cost Efficiency and Long-Term Value

While tool cost is always a consideration, focusing solely on the purchase price can be misleading. A well-defined understanding of cutting tool requirements for general engineering considers long-term value rather than upfront cost.

High-quality tools may have a higher initial price but offer:

- Longer service life

- Reduced scrap rates

- Lower downtime

- Improved productivity

This makes them a cost-effective choice over time.

Quality Standards and Supplier Reliability

Reliable tool suppliers play a critical role in meeting fabrication demands. Consistent quality, technical support, and dependable delivery schedules contribute to smooth production planning.

Working with experienced manufacturers who understand general engineering cutting tools ensures access to application-specific guidance and dependable tooling solutions.

Conclusion

Meeting the cutting tool requirements for general engineering is about selecting tools that deliver precision, durability, and flexibility in a demanding fabrication environment. From material selection and tool geometry to machine compatibility and long-term cost efficiency, every factor contributes to successful machining outcomes.

Fabrication units that invest in high-quality fabrication cutting tools and reliable industrial machining tools benefit from improved productivity, reduced downtime, and consistent output quality. By choosing the right tooling strategy—including the use of advanced carbide cutters for fabrication—general engineering workshops can maintain competitiveness and meet evolving industrial demands with confidence.