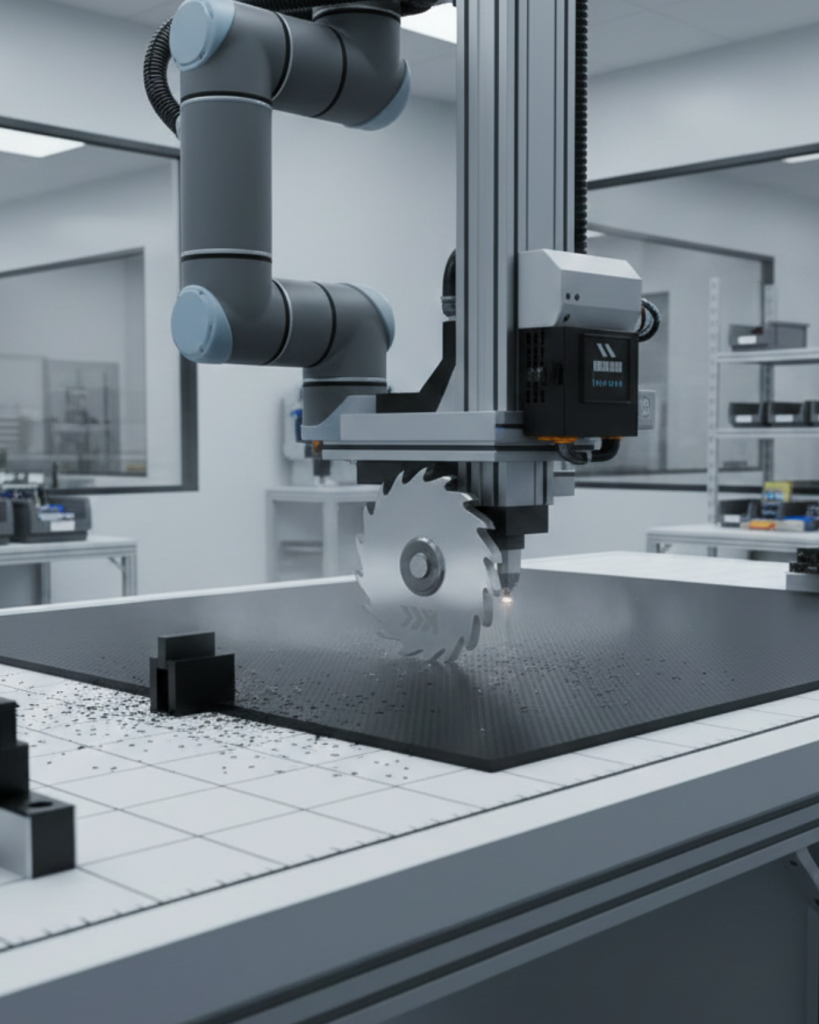

Precision manufacturing demands absolute accuracy, repeatability, and reliability. Whether producing critical machine components or high-tolerance industrial parts, even the smallest deviation can lead to rejection or performance failure. In such environments, standard cutting tools often fall short. This is where customised solid carbide cutters play a crucial role.

Designed to match specific machining requirements, customised tools help manufacturers achieve tighter tolerances, better surface finishes, and improved productivity. As machining complexity increases, the need for application-specific tooling becomes essential in modern precision manufacturing.

Understanding Customised Solid Carbide Cutters

Customised solid carbide cutters are cutting tools engineered to exact specifications based on the workpiece material, machine type, and machining operation. Unlike standard off-the-shelf tools, these cutters are tailored in terms of geometry, dimensions, and cutting characteristics.

High-quality solid carbide cutters offer exceptional hardness, rigidity, and thermal stability, making them ideal for demanding machining environments where precision is non-negotiable.

Why Solid Carbide Is Preferred in Precision Manufacturing

Solid carbide is widely used in precision tooling due to its superior material properties:

- High hardness for excellent wear resistance

- Strong edge stability under heavy cutting loads

- Ability to maintain accuracy at high cutting speeds

- Resistance to heat and deformation

These characteristics make carbide the foundation of high-performance precision manufacturing cutters.

Key Advantages of Customised Solid Carbide Cutters

1. Exact Match to Application Requirements

One of the biggest advantages of customised solid carbide cutters is their ability to match exact machining requirements. Tool dimensions, cutting angles, and profiles are designed specifically for the job.

This eliminates compromises often made with standard tools and results in improved machining efficiency and accuracy.

2. Improved Dimensional Accuracy

Precision manufacturing requires tight tolerances and repeatable results. Customised tools are designed to deliver consistent dimensions across multiple production cycles.

By maintaining edge sharpness and rigidity, custom carbide cutting tools help achieve superior dimensional control and surface finish quality.

3. Enhanced Tool Life

Customised cutters are engineered to distribute cutting forces more evenly, reducing localised stress on the cutting edge. This directly contributes to longer tool life.

When compared to generic tools, customised solid carbide cutters experience less premature wear and chipping, even in demanding applications.

4. Higher Productivity in CNC Precision Machining

CNC machines operate at high speeds and require stable, vibration-free tooling. Customised cutters designed specifically for CNC setups allow higher feed rates and faster cycle times.

Optimised CNC precision machining performance leads to improved output without sacrificing quality.

5. Reduced Number of Operations

Custom tools can often combine multiple machining steps into a single operation. This reduces setup time, tool changes, and machine idle time.

For precision manufacturers, this operational efficiency translates into faster turnaround times and lower production costs.

Role of Tool Geometry in Customised Cutters

Tool geometry is a critical factor in cutter performance. Customisation allows optimisation of:

- Rake and clearance angles

- Cutting edge design

- Chip breaker geometry

- Tool length and neck dimensions

These factors directly influence cutting stability and surface finish, making custom carbide cutting tools essential for complex machining tasks.

Performance Across Different Materials

Customised solid carbide cutters are designed to perform efficiently across a wide range of materials, including:

- Hardened steels

- Stainless steel

- Cast iron

- Alloy steels

- Non-ferrous metals

Tailoring the cutter geometry to material properties ensures smooth cutting and consistent tool performance.

Importance of Coatings in Customised Carbide Cutters

In many precision applications, coatings further enhance cutter performance. Advanced coatings improve heat resistance, reduce friction, and extend tool life.

When combined with optimised geometry, coated solid carbide cutters deliver outstanding performance in high-speed and dry machining conditions.

Cost Efficiency Through Custom Tooling

Although customised tools may involve a higher initial investment, they provide long-term cost benefits:

- Reduced tool consumption

- Lower scrap rates

- Improved machine utilisation

- Fewer production interruptions

These factors make customised solid carbide cutters a cost-effective solution for precision manufacturing operations.

Industry Applications of Customised Carbide Cutters

Custom tooling is widely used in industries such as:

- Automotive and auto components

- Aerospace and defence

- Tooling and die manufacturing

- Medical equipment

- Precision engineering

In each of these sectors, accuracy and consistency are critical, making customised tooling a strategic advantage.

Choosing the Right Tool Manufacturer

The success of customised tooling depends heavily on the manufacturer’s expertise. Experienced manufacturers understand application challenges and provide technical guidance throughout the design process.

Partnering with a reliable supplier ensures precision manufacturing cutters that meet exact requirements and deliver consistent results.

Conclusion

In today’s high-precision manufacturing environment, standard cutting tools often cannot meet complex machining demands. Customised solid carbide cutters offer a tailored solution that enhances accuracy, tool life, and productivity.

By combining advanced material properties, optimised geometry, and application-specific design, these tools play a vital role in CNC precision machining and high-tolerance manufacturing. For businesses focused on quality, efficiency, and long-term performance, investing in custom carbide cutting tools is a strategic decision that delivers measurable results.