In modern machining environments, productivity and precision are no longer optional—they are essential. As materials become harder and production timelines tighter, cutting tools are expected to perform consistently under extreme conditions. One of the most effective ways manufacturers achieve this is through advanced cutter coatings.

Understanding how cutter coatings improve tool life and enhance machining accuracy helps engineering and fabrication units make informed tooling decisions. Coated cutting tools are now widely used across industries due to their ability to withstand heat, reduce wear, and deliver consistent machining results over extended production runs.

What Are Cutter Coatings?

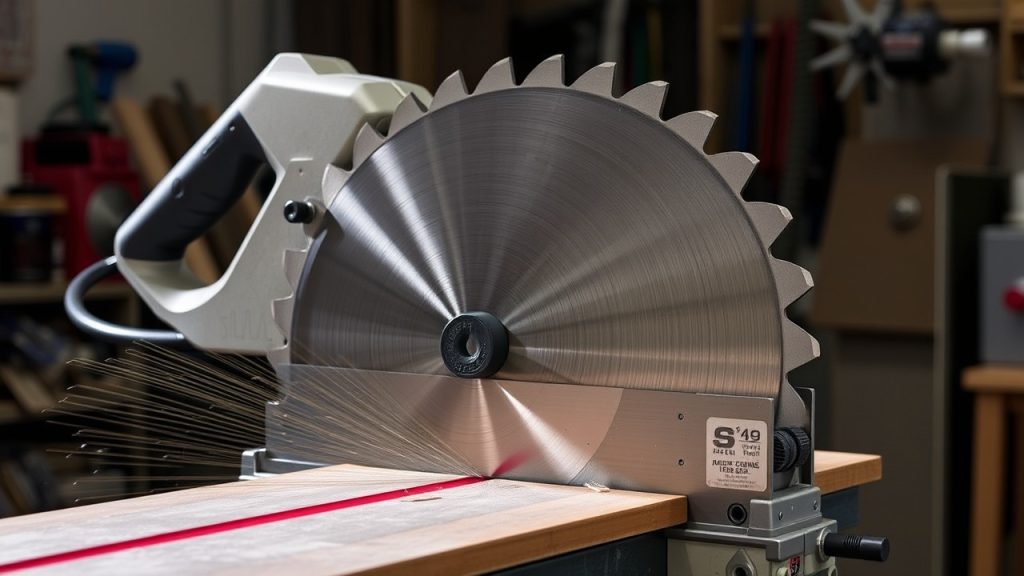

Cutter coatings are thin, engineered layers applied to the surface of cutting tools to improve their performance during machining operations. These coatings act as a protective barrier between the cutting edge and the workpiece material.

Modern carbide cutter coatings are applied using advanced processes such as Physical Vapour Deposition (PVD) or Chemical Vapour Deposition (CVD). These processes ensure strong adhesion, uniform coating thickness, and long-lasting performance.

Why Coatings Are Essential in Modern Machining?

Uncoated tools experience direct contact with workpiece materials, leading to faster wear, higher heat generation, and reduced dimensional accuracy. Coated tools, on the other hand, are designed to operate efficiently under demanding machining conditions.

One of the primary reasons cutter coatings improve tool life is their ability to reduce friction and heat at the cutting interface. This directly impacts tool durability and machining consistency.

Key Benefits of Coated Cutting Tools

1. Extended Tool Life

The most significant advantage of coated tools is increased durability. High-quality coatings protect the cutting edge from abrasion, oxidation, and chemical wear.

By reducing direct metal-to-metal contact, coated cutting tools significantly extend tool life in machining applications. This allows manufacturers to run longer production cycles without frequent tool changes.

2. Improved Heat Resistance

Heat is one of the biggest enemies of cutting tools. Excessive heat leads to edge deformation, premature wear, and loss of accuracy.

Advanced coatings create a thermal barrier that reflects heat away from the tool body. This thermal stability is a major reason cutter coatings improve tool life, especially during high-speed and dry machining operations.

3. Enhanced Machining Accuracy

Dimensional accuracy is critical in precision manufacturing. Worn or unstable cutting edges often result in inconsistent dimensions and poor surface finish.

Coatings help maintain a sharp, stable cutting edge, which directly improves machining accuracy. This ensures consistent tolerances and reduces the need for rework or secondary finishing operations.

4. Reduced Friction and Smoother Cutting

Low-friction coatings allow chips to flow smoothly away from the cutting zone. This reduces cutting forces and vibration during machining.

Smoother cutting action not only improves surface finish but also helps maintain tool life in machining by preventing edge chipping and built-up material on the cutter.

Common Types of Cutter Coatings

Titanium Nitride (TiN)

TiN is one of the most widely used coatings. It offers good wear resistance and reduces friction, making it suitable for general-purpose machining.

Titanium Aluminium Nitride (TiAlN)

TiAlN coatings provide excellent heat resistance and are ideal for high-speed machining of hardened steels. They are commonly used on carbide cutter coatings designed for demanding applications.

Aluminium Chromium Nitride (AlCrN)

AlCrN coatings perform exceptionally well in high-temperature environments and offer superior oxidation resistance, making them suitable for continuous production runs.

Each coating type serves a specific purpose, and selecting the right one plays a critical role in how cutter coatings improve tool life.

Impact of Coatings on Different Workpiece Materials

Different materials require different coating characteristics:

- Steel and Stainless Steel: Heat-resistant coatings improve edge stability and reduce wear

- Cast Iron: Wear-resistant coatings protect against abrasive particles

- Aluminium: Low-friction coatings prevent material build-up on cutting edges

Matching the right coating to the workpiece material ensures optimal performance and consistent machining accuracy.

Coated Tools in CNC Machining

CNC machining demands repeatability, stability, and high-speed performance. Coated tools are particularly beneficial in CNC environments where cutting conditions remain consistent over long runs.

The use of coated cutting tools in CNC machining allows manufacturers to:

- Increase cutting speeds

- Maintain tighter tolerances

- Reduce downtime due to tool changes

- Improve overall production efficiency

This reinforces how cutter coatings improve tool life in automated manufacturing systems.

Cost Efficiency and Productivity Gains

Although coated tools may have a higher upfront cost, they deliver significant long-term savings. Extended tool life, reduced scrap rates, and improved machining consistency result in lower overall production costs.

From a business perspective, investing in advanced carbide cutter coatings leads to:

- Fewer tool replacements

- Reduced machine stoppages

- Higher output per shift

These benefits directly contribute to improved profitability and operational efficiency.

Importance of Coating Quality and Application

Not all coatings perform equally. The effectiveness of a coating depends on:

- Coating thickness and uniformity

- Adhesion strength

- Compatibility with base tool material

Poorly applied coatings can peel or crack, negating their benefits. Working with experienced cutting tool manufacturers ensures coatings are applied using proven processes and quality controls.

When to Choose Coated vs Uncoated Tools

While coated tools are ideal for high-speed and demanding applications, uncoated tools may still be suitable for:

- Low-speed machining

- Soft materials

- Short production runs

Understanding application requirements helps manufacturers choose the right solution and maximise tool life in machining.

Conclusion

Advanced cutter coatings play a crucial role in modern manufacturing by enhancing performance, accuracy, and durability. By reducing heat, friction, and wear, cutter coatings improve tool life and help maintain consistent machining results across demanding applications.

From improved machining accuracy to longer tool life in machining, coated cutting tools offer measurable benefits for general engineering, fabrication, and precision manufacturing units. When combined with high-quality base materials and proper application, carbide cutter coatings become a powerful tool for achieving efficiency, reliability, and long-term cost savings.